Content:

A screw wood splitter is a device for splitting firewood, made industrially or by hand. It is considered useful both in the subsidiary plots for the homeowner, who provides heating with wood, and in the country, where there is no gas and cooking is done on the stove. In industrial production, the device better suits its purpose. But home-made will serve the owner no worse and will cost much cheaper than purchased ones, the minimum price for which is from 15 thousand rubles *.

Screw cleaver - what is it and how to use it

The wood splitter was invented to facilitate the work of a person who is forced to chop wood for heating. Features of the structure and energy used in such devices are diverse and purposeful. Often, the choice of a suitable tool is based on the type of wood. Hard varieties of trees are best processed with a machine that runs on electricity; less complex types of wood are easily amenable to mechanical devices.

Screw cone wood splitter

It does not matter what kind of tool the tool belongs to, whether it is household or industrial, the main division occurs according to the principle of operation. These are three common types:

- The cheapest of all (from 6 thousand rubles *.) - mechanical. A simple device that does not require special instructions. The log for processing is placed on a metal frame, after which force is applied to it using an impact tool. A sharp blade placed on the machine allows you to split wood several times faster than with an ax. At the same time, energy is spent several times less. The positive aspects are the cost and ease of assembly, but the negative ones include the lowest performance of all the available varieties.

- The most popular type is the screw cone wood splitter. The principle of operation differs from hydraulic or mechanical by the presence of the main working part, from which the machine got its name. The cone wood splitter "carrot", as it is called in industrial slang, works from the cone, which got its name from the shape of the working part. The pivot pin driving the main work piece is powered by an electricity source. This may be the simplest electric motor, in search of which folk craftsmen do not particularly bother. Often they use an old one from a washing machine or other functional device that has become unusable, but has kept the motor in good order.

- The principle of operation of the hydraulic device is simple; during its operation, the energy is directed to the hydraulic cylinder. The cylinder redirects it to the stem, and the stem makes the stop work. The power of such a device depends on the volume of the cylinder, but even a small one in volume can create a powerful enough force to split a wooden block. Either a tree or a knife can move, but the pressure exerted is still enough to split.

Do-it-yourself cone log splitter

Cone log splitter requirements

The tool that is considered optimal for harvesting wood fuel must meet certain requirements. This applies to any of the existing types, hydraulic, mechanical and cone. The kone log splitter must have the following parameters for successful work:

- working length (this is the name of the distance between the wedge and the piston, 50 cm is considered optimal);

- good splitting power (5-7 tons are considered standard), necessary for trouble-free splitting of the workpiece;

- a sufficient rotation speed (not less than 400 rpm, but not more than 600) to apply a directed force to the wood fibers;

- the second indicator of speed is the movement of the piston, which is usually done 4 cm / sec forward and 7.5 cm / sec - in the opposite direction;

- the presence of a travel stop, which simultaneously increases productivity and reduces the consumption of energy consumed;

- sufficiently powerful engine (about 3-4 kW);

- the shape and functionality of the screw, where the minimum operating speed determines the performance of both an industrial and home-made device, in which the screw plays one of the defining roles.

Size, power and maximum performance are three factors in the cost of purchasing a device made in an industrial environment.

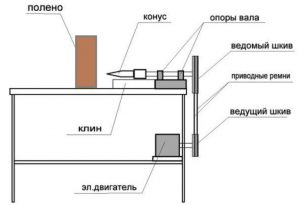

Screw wood splitter diagram

Characteristics, advantages and disadvantages of a screw cleaver

A device with a screw is easy to distinguish even by its appearance. The centrally located wood splitter works on the principle of screwing a hardware part into a tree. An electric motor is located on the back, thanks to which the device works. The rotation is carried out until reaching the ultimate point of fiber strength, after which the workpiece is split. The threaded cone nozzle gradually becomes thinner towards the working part, turning into a narrow tip, thanks to which it is easy to enter the wood. The more significant the dimensions and more powerful the motor, the faster it is possible to make logs from a wooden chock.

The main advantage is the extreme simplicity of the design. A two-phase motor is required, with a power of 3-4 kW. For home use, an 80 mm screw diameter is sufficient, with a device length of 250 mm. The disadvantage is the low level of safety during work and the need to independently bring the workpieces. This does not exclude physical fatigue during work, although it significantly speeds up the process of chopping wood. The fastest is the Kone wood splitter model, which can process 5 cubic meters of firewood in 2 hours.

What you need to make a screw wood splitter

First of all, it is necessary to have a basic part that cannot be made at home without special equipment - wood splitter cone. Drawings and dimensions, measured and made in advance, allow you to use improvised means found on the farm and complete a home-made device in a budget option. But the manufacturers sell the cone for the wood splitter separately, because it is made using special technologies. You will need a bed, an electric motor, a work area and a pedestal on which the cone is attached.

Log splitter with gear

Preparatory work: approximate dimensions and drawings

Folk craftsmen place detailed instructions for making and carrying out work in videos. The purchase or search for spare parts for the wood splitter should be carried out after the drawing is made, and the assembly - after watching the video. Here is the whole process in sequence, demonstrating how to equip the bed, install the electric motor and place the working shaft:

The design scheme is simple, and almost everywhere it is drawn up according to the same principle.

Step-by-step assembly instructions

The assembly sequence depends on the design used. In general, without much detail, the manufacturer only needs to assemble the bed. After that, the cone working shaft assembly is assembled. Then the pulleys and the actual cone are installed, which is mounted on the screw shaft. Next, a reverse, a divider, an RCD, wiring is equipped.

If you need a powerful unit with high performance, it is easier to buy a ready-made one, or to rent it. The more power of the unit, the less likely it is to assemble it yourself.

* Prices are valid for October 2018