Content:

Potatoes have always been considered one of the main vegetables in the kitchen. It is used to prepare first and second courses, desserts, etc. The cultivation of this vegetable is associated with high labor costs, because in order to obtain a good harvest, it is necessary to huddle potato bushes several times per season.

Thanks to hilling, oxygen access to the roots improves, channels in the ground are destroyed, as a result of which moisture evaporates less, and the number of tubers also increases.

Hilling bushes is carried out in suburban areas mechanically using a hoe. However, this is a long and arduous process.

To help farmers and gardeners specializing in growing potatoes, a special tool has been created called a hiller.

Advantages and disadvantages of hillers

The use of mechanisms always allows you to increase labor productivity on farm and summer cottages.

Benefits:

- reduces labor costs and increases the efficiency of the farmer;

- can be a multifunctional tool that can be additionally used for loosening the soil, planting potatoes, as well as during harvesting;

- You can freely buy a potato beaker in a store or make it yourself.

Disadvantages:

- in order to use the device, it is necessary to purchase it, which means that material costs for the purchase and further maintenance will be required;

- when working with the device, you must follow the safety instructions.

Types of potato growers

Depending on the design, the following types of devices are distinguished:

- listeric;

- disk;

- propeller.

The propeller mechanisms allow you to move the soil between the rows into the grooves.

The most common are lister and disk devices.

Lister mechanisms

They are produced with an adjustable angle of attack (angle of inclination of the cutting part of the hiller to the ground) and fixed.

Adjustable ones allow you to change the depth of loosening and, accordingly, the coverage area.

Advantages of the device:

- consumes less power compared to disk devices;

- simpler in design;

- the price is less than a disk device;

- has a low weight, therefore it works perfectly on low-power mechanisms (walk-behind tractors and cultivators).

Disadvantages:

- does not work well on wet and heavy soil;

- planting potatoes should only be flat, with a strictly fixed row spacing.

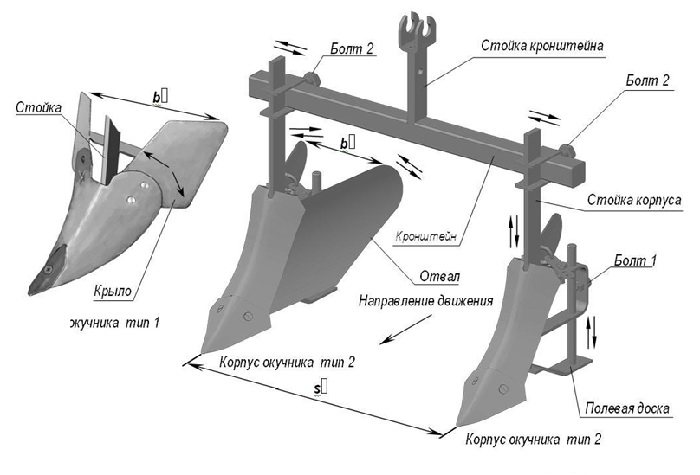

Disc hillers

Structurally, they consist of two discs with a sharpened edge. When the hiller moves, the discs rotate and crush the soil. They have a convex shape. Due to this form, the soil is simultaneously loosened and an earthen roller is formed.

The discs are attached through ball bearings to the racks, which are located on a horizontal holder frame.

Advantages:

- better performance of hilling, the ridges are smoother and higher;

- can be used with different row spacing;

- allows for hilling on heavier soils.

Disadvantages:

- higher price;

- higher fuel consumption.

Depending on the volume of work performed and the degree of mechanization, the potato tiller is:

- manual;

- automated.

Manual - moves due to the fact that a person pushes or pulls the mechanism.

The automated potato bucket is an additional suspension device for a walk-behind tractor, cultivator or tractor.

Manual potato ridger

Allows you to process potato beds, regardless of the presence of a walk-behind tractor or a tractor. For manual types, the most common designs are lister and disc mechanisms.

Advantages:

- can be used in areas where the use of motoblocks or tractors is impossible or impractical;

- cheaper in terms of purchase and maintenance.

Disadvantages:

- more expenditure of physical forces of the employee;

- processing of the site takes longer;

- lower quality processing of plantings is possible;

- when working with the mechanism, two people are needed: one must pull the potato bucket forward, and the second must push it from behind with the help of handles.

To make it easier to operate the manual mechanism, and so that one person can handle it, you can upgrade the manual hiller by equipping it with a bicycle wheel. In this case, the plow is attached to the bike frame. The steering wheel allows you to direct the device in the desired direction. Why is it convenient to use a bike? Because it is lightweight and the steering wheel is at the optimum height for the job.

Tractor hiller

These devices allow loosening the soil and hilling potatoes.

The design includes:

- metal frame;

- hitch;

- two wheels (usually stamped);

- lancet paws;

- dumps.

The tines are designed for cutting the soil to a depth of about 150 mm when hilling. Thus, the mechanism can be used as a plow for potatoes.

The attachment is fixed to the tractor using a hitch. Lattice plows are used directly for hilling plants.

If there is no need to loosen the soil, then unscrew the paws.

Usually, such a device is used in conjunction with tractors that have a small traction force, for example, the T-25.

Tiller for walk-behind tractor

To fix it to the walk-behind tractor, you must first dismantle the opener and install a device in its place. Potato pickers designed for walk-behind tractors can also be installed on a mini tractor.

The industry produces not only single-row, but also two, three and n-row mechanisms, which can speed up the hilling process.

For cultivators and walk-behind tractors with an engine similar to the Neva-type walk-behind tractor, a rotary mechanism can be used. In this case, the wheelset is removed from the walk-behind tractor, and a hiller is installed on the gearbox shaft.The cogwheels perfectly grind the soil, pruning weed roots, and at the same time hilling the potato beds.

Potato pickers can be installed on mechanisms with gasoline or electric motors. In this case, electric potatoes for processing potatoes are lighter and more mobile.

You can buy the device without any problems in any city in the country, be it Moscow, Novgorod or Rostov. Usually, a specialized store allows you to buy a hiller of the desired type, but most often you can purchase a Chinese product that is far from adequate quality.

So that you have a reliable assistant in your country house or on a farm, you can make a homemade manual or automated tiller for processing potatoes.

Homemade lister hiller

To make a homemade manual or automated tiller for any type of potato, you first need to make a drawing of the mechanism on paper to scale and indicate the required dimensions of the device.

Manufacturing equipment

In order for the work to be done quickly and efficiently, you must first prepare the tool. For this you will need:

- Bulgarian;

- welding machine with electrodes;

- drill with a set of drills;

- hammer.

From the materials you need to prepare:

- metal sheet, 2-3 mm thick;

- iron pipe, with a section of 20mmx20mm or 30mmx30mm;

- if an adjustable fixture is made, then additionally you need to purchase 4 hinges and metal strips (3 mm thick).

Progress

- We cut out the sides of the plow (ears) from a metal sheet. The wider the width of the sides, the more land will be captured and, accordingly, more of it will be covered under the bush. In the narrower part, intended for cutting the ground, the width of the ears should be 5-7 cm. For narrow row spacings, ears are made of smaller width than for wide ones;

- Bend the sidewalls and give them the desired shape. The bending radius should be the same for both the left and right halves;

- We weld both halves and clean the weld spot;

- We connect the ears together with metal strips. If the hiller is not adjustable, then the strips are welded to the ears, if adjustable, then we fix it with loops. It is desirable that the angle between the stripes is 90 ° and between the ears 120 °. We weld the other ends of the strips to each other;

- We attach the nose to the narrow ends of the ears by welding. The angle between the metal stripes and the spout must be 150 °;

- After making the working part of the hiller, it is welded to the bracket. Using the bracket, then the hiller is connected to a mechanism, for example, to a walk-behind tractor.

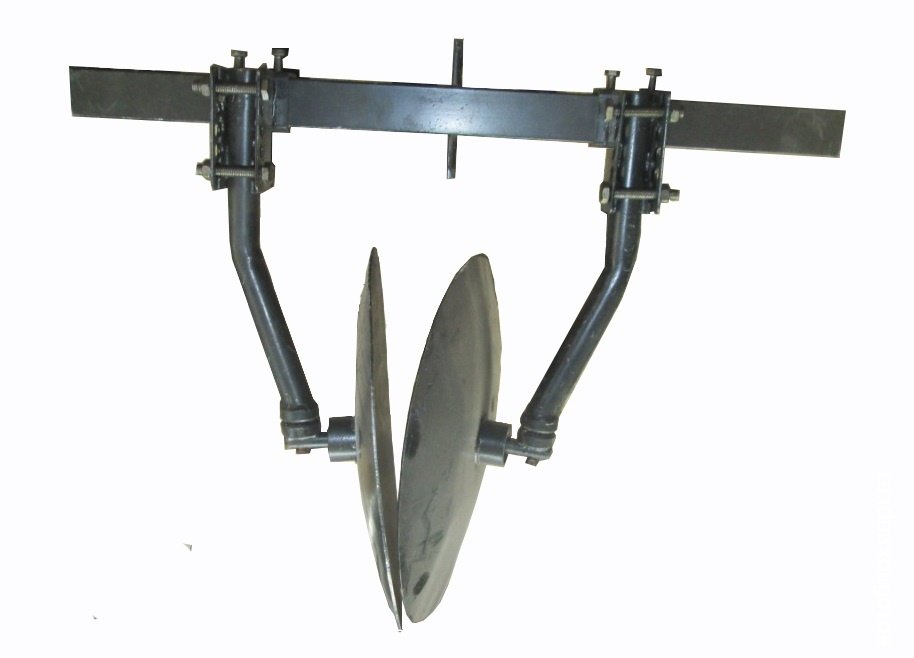

Homemade disc hiller

Consider how you can make a disc hiller for potatoes on a walk-behind tractor with your own hands.

To make discs you will need:

- metal sheet, 3 mm thick, for the manufacture of two circles, 45-50 cm in diameter;

- two screw lanyards (designed to adjust the position of the discs relative to the axis);

- two racks (made of a metal rod with a diameter of at least 30 mm);

- metal pipe;

- two bearings.

Manufacturing procedure

- We sharpen and bend the discs along the edges so that there is a convex part on one side;

- We install them on racks placed in ball bearings and fix them with bolted connections;

- We fix the racks to the metal pipe. The spacing between the tines should match the row spacing. Discs are located at an angle of 10-15 ° in relation to each other;

- If we plan to install it on a walk-behind tractor, then we weld a metal plate to the pipe, which will allow in the future to attach the device to the walk-behind tractor.

The use of hillers will automate the care of potato plantings.